_L.jpg)

Your ideas take form at OKULEN®.

We have been specialists in preformed components since 1993.

This specific manufacturing process presses high-quality plastics into round blanks, rings and form-fitting components with the huge advantage of saving on expensive raw materials while cutting subsequent machining to a minimum.

Four materials, one form.

The tool design allows four materials (PE, PP, PVDF, PFA) to be processed into the same form, giving you huge savings potential and cutting the amortisation period for the tool to a minimum.

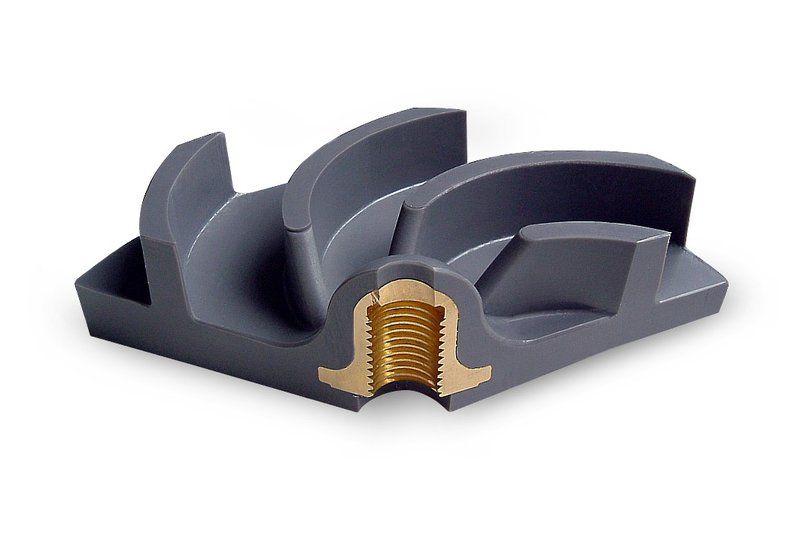

Plastics with metal cores.

The preforming process also allows plastic components to be manufactured with a metal core in one pressing. Precise metal core positioning plays a major role in industries such as chemical pumps, but our components and their properties are also greatly appreciated in the petrochemical, pharmaceutical, and food industries.

We have more than 40 preforming presses, and can respond quickly and accurately to customer requirements. We provide everything from preform construction to possible component reworking in our CNC department from a one-stop shop.

Our machines can handle diameter dimensions from 40 to 1,270 mm.

Depending on the diameter-to-thickness ratio, our presses can process thicknesses of up to 400 mm in one step.

By preference we process

- OKULEN®-PVDF

- OKULEN®-PFA

- OKULEN®-PTFE

- OKULEN®-PP

- OKULEN®-UHMW PE

On request we also include electrical conductivity or fibre-glass reinforcement.

These materials feature good mechanical properties and excellent chemical resistance.